Aluminum alloys are widely used in many industries because of their excellent properties, such as lightweight, resistance to corrosion, and a high strength-to-weight ratio. The most commonly used aluminum alloys include 5052 and 6061; both are broadly used due to their versatility, yet they have distinct properties that make them particularly adapted to specific applications.

The article tries to lay down a comparative analysis between 5052 and 6061 Aluminum, focusing on their chemical and physical properties, mechanical characteristics, and applications in different sectors, including aerospace and automotive. From this comparison, one will have sufficient insight into one's ability to decide which alloy best fits the needs of one's project.

5052 Aluminum vs 6061 Aluminum: Chemical Composition

5052 Aluminum

The major alloying element in 5052 aluminum is Magnesium (Mg), which constitutes 2.2-2.8% of the alloy. This high magnesium content provides excellent strength and very good corrosion resistance, particularly in marine atmospheres and saltwater exposure. It contains, in addition, chromium (Cr) at 0.15-0.35%, added to increase corrosion resistance further and improve the grain structure to ensure a more reliable and homogeneous material.

Other elements: Silicon (Si), Iron (Fe), Copper (Cu), Manganese (Mn), and Zinc (Zn) are found in trace amounts, therefore contributing to the overall characteristics of the alloy without significantly altering its properties.

6061 Aluminum

The major alloying elements of 6061 aluminum are Magnesium (Mg) within the range of 0.8-1.2%, and Silicon (Si) in the range of 0.4-0.8%. Together, these two components form magnesium silicide, which is a phase that increases the mechanical properties of the alloy, such as strength and machinability.

Further, other ingredients such as Chromium (Cr), Iron (Fe), Copper (Cu), Manganese (Mn), Zinc (Zn), and Titanium (Ti) significantly contribute to the strength, corrosion resistance, and the ability to resist stress in various environments of the alloy.

Physical Properties Comparison

Although both 5052 and 6061 aluminum alloys are lightweight, flexible, corrosion resistant, and have quite distinct differences in their properties, these are not unique.

Density

5052 Aluminum has a density of 2.68 g/cm³, somewhat less than 6061, thus making 5052 even lighter. This could be an essential factor in those applications where weight is at the top of the requirements list.

6061 Aluminum is 2.70 g/cm³ in density, so it's a little heavier, but not generally by much unless you're doing precision engineering.

Thermal conductivity

5052 Aluminum: Has a thermal conductivity of 138 W/m·K, which is less than that of 6061 but still capable of dissipating heat efficiently for many applications.

6061 Aluminium has good thermal conductivity, ranging from 151 to 167 W/m·K. This makes it very suitable for applications where heat dissipation is critical, such as heat exchangers and some electronic parts.

Electrical Conductivity

5052 Aluminum has a lower electrical conductivity because of its higher magnesium content and thus is less appropriate for electrical applications.

6061 Aluminum has better electrical conductivity, making it a good aluminum alloy for applications that require high conductivity, such as in electrical circuits and components.

Mechanical Properties Comparison

The mechanical properties of an alloy determine its performance under load-bearing or stress-related applications. The 5052 and 6061 aluminum alloys show different mechanical properties that are applied to different applications.

Tensile strength

The tensile strength of 5052 aluminum ranges from 210 to 260 MPa. It is used in areas where moderate strength is needed.

6061 aluminum has a tensile strength in the range of 290–310 MPa, therefore providing excellent strength for high demanding applications, especially in structural use.

Yield Strength

5052 Aluminum: The yield strength is around 130 MPa, which provides moderate resistance to deformation under stress. Therefore, 5052 is often used in applications requiring only modest strength.

6061 Aluminum has a remarkably higher yield strength of around 240 MPa, which features more resistance to deformation under load. This makes it perfect for structural applications and components that are subjected to considerable stress.

Hardness

The Brinell hardness of 5052 aluminum is approximately 61 HB, which is on the low side. This would suggest that it is easy to machine and form but has lower wear resistance than 6061.

6061 Aluminium with a Brinell hardness of 95 HB possesses higher wear and abrasion resistance, thus making it a better choice for applications with friction or impact.

Fatigue Strength

It possesses intermediate strength under fatigue so appropriate in many applications not intended for high cyclic loading.

6061 Aluminum possesses high fatigue strength, making it an excellent choice for parts that are subject to repeated stress cycles, like those in aerospace or automotive use.

Machinability and Workability

Both alloys, 5052 and 6061, offer excellent machinability; however, there are some differences in performance between the two alloys in machining operations.

Machinability

5052 Aluminum has medium machinability. The high magnesium content makes it somewhat harder to machine than 6061; in many cases, slower speeds and machining parameter control are necessary to avoid tool wear and less-than-optimal surface finishes.

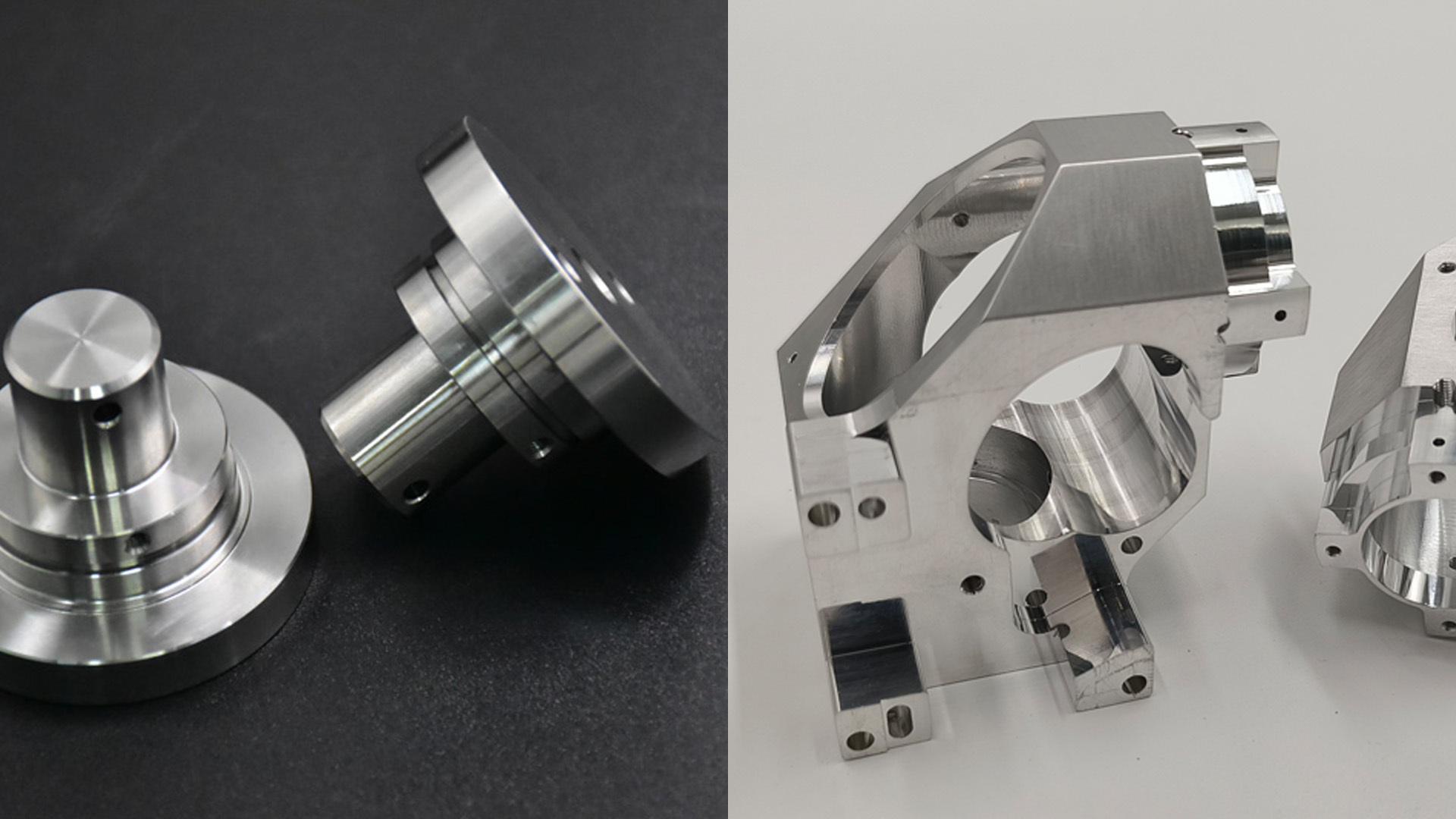

6061 Aluminum has excellent machinability because it contains a balanced content of magnesium and silicon. It can be machined at high speeds with less tool wear, thus giving excellent surface finishes that make the alloy the preferred choice for precision parts and complex designs.

Weldability

5052 aluminum has excellent weldability, making it highly suitable for applications that require extensive welding. It can be welded using various methods, such as TIG and MIG, without the inherent risk of cracking.

6061 Aluminum: While 6061 is also weldable, it requires much closer control in the welding process, as incorrect procedures could result in cracking or defects. In addition, pre- and post-weld heat treatments are often needed to maintain its mechanical properties.

Applications of 5052 Aluminum

Owing to its excellent corrosion resistance, particularly in marine environments, 5052 aluminum is often used where strength and light weight are the primary considerations.

Maritime Industry: 5052 aluminum is widely used in the hulls of boats and ships and their superstructures, among other parts exposed to salty, corrosive seawater in most cases. Its excellent corrosion resistance makes it very attractive under such hostile conditions.

Automotive Industry: 5052 aluminum in the automobile industry is applied for the construction of fuel tanks, panels, and other components. This particular formability, plus the corrosion resistance is pretty desirable for automobile applications.

Consumer Goods: 5052 aluminum can be used in a very wide range of consumer products, from electronics to kitchenware and home appliances, where the product needs to be strong and resistant to corrosion.

Aerospace Applications: Not normally used for critical structural parts, but 5052 is used in non-load-bearing components such as ducts, brackets, and panels where weight savings and corrosion resistance are important.

Applications of 6061 Aluminum

On the other hand, 6061 aluminum is strong and manufacturable; hence, it is versatile for applications that are structurally more demanding.

Structural Elements: 6061 aluminum is used widely in the construction of bridges, buildings, and pipelines. Its high strength and ability to be heat-treated make it suitable for such heavy applications.

Aerospace and Defense: In the aerospace and defense industries, 6061 aluminum is used in critical structural applications, including aircraft frames and components for military vehicles. Its strength and ability to be heat-treated make it an ideal choice for these fields.

Automotive Industry: 6061 Aluminum is used in automotive parts, suspension components, engine parts, and chassis. 6061 Aluminum is of high strength and excellent machining. It is suitable for parts that require close tolerances.

Recreational Equipment: Its high strength and light weight are some reasons 6061 aluminum is very widely used in producing bicycles, sporting goods, and boats- that provides much needed strength but keeps the equipment light and easy to maneuver.

The Choice Between 5052 and 6061 Aluminum

Some considerations one has in selecting between 5052 and 6061 aluminum include

Strength Requirements: When the project demands high tensile and yield strength, then 6061 will be better.

Corrosion Resistance: In corrosive environments, for example, saltwater, 5052 appears to be the better choice.

Machinability and Workability: 6061 is more machinable and formable, while 5052 is a bit tough but has superior ductility and formability.

Budget Constraints: Alloy 5052 tends to be less expensive, making it a more affordable choice for non-structural applications or when corrosion resistance is more important than strength.