Extensive Polyphenylene Ether Manufacturing Plant Project Report: A Comprehensive Analysis

January 16, 2025

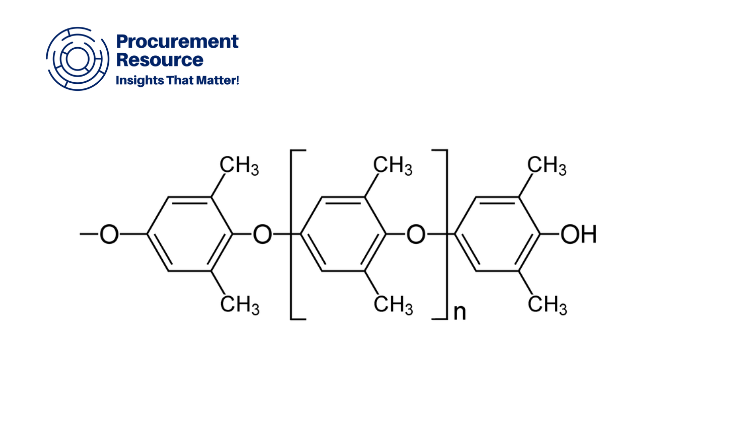

In the dynamic world of chemical manufacturing, polyphenylene ether (PPE) stands out as a versatile and high-performance thermoplastic. Its wide range of applications in automotive, electronics, and industrial components has fueled the growth of its manufacturing sector. For businesses planning to venture into this field, an Extensive Polyphenylene Ether Manufacturing Plant Project Report serves as a critical resource for strategic planning and investment decision-making. This article delves into the key aspects of PPE manufacturing, including cost models, market drivers, manufacturing processes, and more.

Key Insights into the Polyphenylene Ether Manufacturing Sector

1. Cost Model Analysis

Setting up a PPE manufacturing plant involves a comprehensive understanding of cost factors. The cost model encompasses:

Capital Expenditure (CAPEX): This includes the cost of land, machinery, and construction of the manufacturing facility.

Operational Expenditure (OPEX): Regular expenses like raw materials, labor, utilities, and maintenance.

Logistics and Supply Chain Costs: These pertain to the procurement and transportation of feedstocks and finished goods distribution.

Optimizing these costs requires strategic planning, accurate forecasts, and effective resource management—elements often detailed in a well-prepared project report.

2. Key Feedstocks and Raw Materials

The primary raw materials for PPE production include phenols and oxygen. The process requires catalysts and specific conditions to achieve the desired polymer properties. Procuring high-quality feedstocks is essential to ensure superior product performance. Collaborating with established suppliers and leveraging services like Procurement Resource can streamline the sourcing process and enhance cost-efficiency.

Request a Free Sample - https://www.procurementresource.com/reports/polyphenylene-ether-manufacturing-plant-project-report/request-sample

3. Manufacturing Process Overview

The manufacturing of polyphenylene ether typically involves the oxidative polymerization of phenols. Key steps include:

Catalytic Reaction: Phenols are oxidized in the presence of a catalyst to form polyphenylene ether.

Purification and Stabilization: Impurities are removed, and stabilizers are added to enhance the polymer’s durability.

Granulation: The polymer is processed into granules or pellets for easy handling and application.

This process requires advanced equipment and technical expertise to maintain high product standards while minimizing waste and energy consumption.

4. Market Drivers and Trends

The PPE market is driven by:

Growing Demand in Automotive Applications: PPE’s lightweight and heat-resistant properties make it an ideal material for vehicle components.

Advancements in Electronics: With increasing demand for miniaturized and durable electronic devices, PPE’s insulation properties are highly valued.

Sustainability Goals: PPE’s recyclability and reduced environmental impact align with global sustainability objectives, boosting its market appeal.

5. Top Manufacturers in the PPE Market

Some leading players in the polyphenylene ether industry include:

SABIC Innovative Plastics

Asahi Kasei Corporation

Mitsubishi Chemical Holdings Corporation

Ensinger GmbH

These manufacturers leverage state-of-the-art technologies and extensive R&D capabilities to cater to diverse market demands.

Why Opt for a Detailed Project Report?

An Extensive Polyphenylene Ether Manufacturing Plant Project Report provides a holistic view of the manufacturing landscape. It aids investors and stakeholders in:

Identifying key cost drivers and optimizing resources.

Understanding market trends and competitive positioning.

Gaining insights into regulatory compliance and sustainability requirements.

Such a report is indispensable for businesses aiming to minimize risks and maximize returns in the PPE manufacturing sector.

Request a Free Sample

Are you planning to set up a polyphenylene ether manufacturing plant? Get access to an in-depth project report tailored to your requirements. The report includes:

Cost breakdown and financial analysis.

Detailed manufacturing process flow.

Insights into market drivers and challenges.

Request Your Free Sample Report - https://www.procurementresource.com/reports/polyphenylene-ether-manufacturing-plant-project-report/request-sample

Leveraging Procurement Resource for Success

Efficient procurement is the cornerstone of any successful manufacturing venture. Procurement Resource offers valuable insights and tools to streamline your supply chain, reduce costs, and ensure uninterrupted operations. With expertise in sourcing feedstocks and analyzing market trends, they are a trusted partner for businesses in the PPE industry.

Contact Us:

Company Name: Procurement Resource

Contact Person: Tom Hanks

Email: sales@procurementresource.com

Toll-Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537171117 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA