Guide to Industrial Motor Wiring and Connections

December 25, 2025

Introduction to Motor Wiring

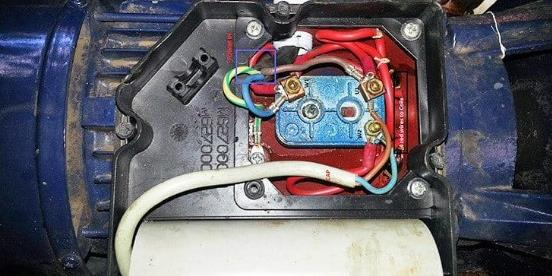

Proper wiring is crucial for the safe and efficient operation of industrial motors. Incorrect connections can lead to motor failure, reduced performance, or even safety hazards. Understanding the electrical configuration and following manufacturer guidelines is essential for technicians and engineers. One important resource for Cummins and Siemens motor operators is the siemens 1ph8 motor wiring diagram, which provides detailed guidance on proper electrical connections.

Understanding the Wiring Diagram

A wiring diagram serves as a visual representation of the motor’s electrical circuits. For the siemens 1ph8 motor, the diagram illustrates how power is distributed, how internal components are connected, and the locations of terminals and connectors. By consulting this diagram, technicians can ensure correct installation, troubleshoot issues, and maintain safe operations.

Key Components in the Diagram

- Power Terminals: Indicate where incoming power lines connect to the motor.

- Control Terminals: Show connections for control devices, including switches and relays.

- Ground Connections: Ensure safe operation by preventing electrical shocks or short circuits.

- Internal Components: Include connections to windings, brushes, and sensors where applicable.

Importance of Accurate Wiring

Safety Considerations

Proper wiring is critical to avoid electrical hazards. Incorrect connections can result in short circuits, overheating, or electrical shocks. By following the siemens 1ph8 motor wiring diagram, technicians can minimize the risk of accidents during installation and operation.

Performance Optimization

The wiring configuration affects motor performance, including torque output, speed stability, and energy efficiency. Accurate wiring ensures that the motor operates within its designed specifications, providing reliable and efficient performance.

Maintenance and Troubleshooting

Having access to the wiring diagram simplifies maintenance and troubleshooting. Technicians can quickly identify faults, check connections, and ensure all components are functioning correctly. This reduces downtime and prevents costly repairs.

Step-by-Step Guide to Using the Wiring Diagram

Step 1: Identify Terminals and Connectors

Start by locating all power, control, and ground Siemens 1ph8 motor wiring diagram terminals as shown in the diagram. Ensure each connection point is clearly understood before beginning wiring.

Step 2: Verify Electrical Supply

Confirm that the voltage and current ratings match the motor’s specifications. Using the wrong power supply can damage the motor or reduce efficiency.

Step 3: Connect Power and Control Lines

Follow the diagram to connect incoming power lines to the correct terminals. Connect control devices such as switches or relays according to the wiring diagram instructions.

Step 4: Ensure Proper Grounding

Ground connections are essential for safety and stability. Verify that all grounding points are secure and compliant with electrical standards.

Step 5: Test the Motor

After completing the wiring, perform a test run to ensure the motor operates correctly. Monitor performance parameters, such as current draw, speed, and vibration, to confirm proper wiring.

Common Wiring Issues and Solutions

Overheating

Overheating often occurs due to incorrect connections or excessive load. Verify wiring against the siemens 1ph8 motor wiring diagram and ensure proper load management.

Vibration or Noise

Improper wiring can cause irregular torque or uneven current distribution, leading to vibration or noise. Recheck connections and correct any discrepancies according to the diagram.

Motor Does Not Start

If the motor fails to start, it could be due to missing connections or reversed polarity. Use the wiring diagram to systematically check each terminal and ensure all connections are correct.

Best Practices for Motor Wiring

- Always refer to the manufacturer’s wiring diagram before installation.

- Use proper tools and insulated connectors to ensure safety.

- Label all wires to simplify future maintenance.

- Regularly inspect wiring for signs of wear or damage.

- Follow local electrical codes and safety regulations.

Applications of Siemens 1PH8 Motor

The siemens 1ph8 motor is widely used in industrial applications due to its reliability and performance. Common applications include:

- Conveyor systems in manufacturing plants.

- Pumps and compressors in processing facilities.

- Automation equipment and robotics.

- HVAC systems and other industrial machinery.

Accurate wiring ensures these motors perform efficiently across all applications, reducing downtime and extending service life.

Conclusion

Understanding motor wiring is critical for safe and efficient operation of industrial equipment. A siemens 1ph8 motor wiring diagram provides detailed guidance on electrical connections, helping technicians install, maintain, and troubleshoot motors effectively. Proper wiring ensures safety, optimizes performance, and prolongs motor life. By following the wiring diagram and adhering to best practices, industries can achieve reliable and efficient operation of their equipment.