In today's rapidly evolving technological landscape, businesses across various sectors constantly seek innovative solutions to streamline their operations, enhance efficiency, and stay ahead of the competition. One such groundbreaking technology making waves in multiple industries is oprekladač. Let's delve into what oprekladač is, how it works, its applications, benefits, challenges, and what the future holds for this transformative technology.

A brief overview of what oprekladač is

Oprekladač, a term derived from the Slovenian language, encompasses a range of automated systems designed to perform tasks traditionally carried out by human operators. From simple repetitive actions to complex decision-making processes, oprekladač systems leverage advanced algorithms, sensors, and actuators to execute various functions precisely and efficiently.

Importance of oprekladač in various industries

Across industries such as healthcare, manufacturing, automotive, retail, and beyond, oprekladač technology is revolutionizing workflows, driving productivity, and opening up new possibilities for innovation.

Understanding Oprekladač

Definition and origins of oprekladač

"oprekladač" originated from the Slovenian word "prekladati," meaning to shift or transfer. Initially used to describe manual labour, the concept evolved with the advent of automation and robotics, giving rise to modern oprekladač systems.

Evolution of oprekladač technology

From early mechanized processes to sophisticated AI-driven solutions, the evolution of oprekladač technology mirrors advancements in computing power, machine learning, and robotics. Today's oprekladač systems can handle increasingly complex tasks with speed and accuracy.

How Oprekladač Works

Mechanisms behind oprekladač operation

Oprekladač systems rely on hardware and software components to execute tasks. Sensors gather data from the environment, which algorithms process to make informed decisions. Actuators then carry out the necessary actions based on these decisions.

Components involved in oprekladač systems

Key components of oprekladač systems include:

- Sensors for perception.

- Processors for computation.

- Actuators for action.

- Communication interfaces for interaction with other systems.

Applications of Oprekladač

Oprekladač in the healthcare industry

In healthcare, oprekladač systems assist with patient monitoring, medication dispensing, and surgical procedures, improving patient outcomes and reducing the burden on healthcare professionals.

Oprekladač in the manufacturing sector

In manufacturing, oprekladač technology is employed for assembly, packaging, and quality control, leading to increased production rates, higher product quality, and improved workplace safety.

Oprekladač in the automotive industry

Automotive companies utilize oprekladač systems for tasks ranging from welding and painting to assembly and inspection, enhancing efficiency and precision in the production process.

Oprekladač in retail and e-commerce

In retail and e-commerce, oprekladač systems streamline warehouse operations, optimize inventory management, and enhance order fulfilment processes, resulting in faster delivery times and improved customer satisfaction.

Benefits of Using Oprekladač

Efficiency improvements with oprekladač

By automating repetitive tasks and optimizing workflows, oprekladač systems significantly increase operational efficiency, allowing businesses to accomplish more in less time.

Cost-saving advantages

Oprekladač technology helps businesses reduce labour costs, minimize errors, and optimize resource utilization, leading to substantial cost savings over time.

Enhanced accuracy and precision

With precise control and consistent performance, oprekladač systems minimize errors and variability, resulting in higher product quality and reliability.

Challenges and Limitations of Oprekladač

Technical challenges faced by oprekladač systems

Despite their capabilities, oprekladač systems encounter challenges such as sensor limitations, environmental variability, and algorithm complexity, impacting performance and reliability.

Limitations in certain applications

In tasks requiring human creativity, intuition, or adaptability, oprekladač systems may struggle to match the capabilities of human operators, posing limitations in certain applications.

Future Trends in Oprekladač Technology

Advancements in oprekladač technology

Continued advancements in AI, robotics, and automation drive the development of more sophisticated oprekladač systems capable of handling increasingly complex tasks with greater autonomy.

Potential future applications

From autonomous vehicles and delivery

From drones to robotic assistants and smart factories, the potential applications of oprekladač technology are vast and diverse, promising to reshape industries and society.

Choosing the Right Oprekladač System

Factors to consider when selecting oprekladač technology

When evaluating oprekladač systems, businesses should consider performance, reliability, scalability, integration capabilities, and return on investment.

Key features to look for

Important features in oprekladač systems include:

- Robust sensing and perception capabilities.

- Intelligent decision-making algorithms.

- Adaptive control mechanisms.

- Seamless connectivity with other systems.

Implementing Oprekladač in Your Business

Steps to integrate oprekladač into your operations

The successful integration of oprekladač technology requires careful planning, stakeholder buy-in, and technical expertise. Key steps include assessing needs, selecting the right system, designing workflows, and providing employee training.

Training and adaptation for employees

To ensure smooth transition and adoption, employees should receive comprehensive training on operating and interacting with oprekladač systems and opportunities for upskilling and reskilling.

Case Studies: Success Stories with Oprekladač

Real-world examples of companies benefiting from oprekladač

Case studies highlight the tangible benefits of oprekladač technology across various industries, showcasing productivity, quality, safety, and competitiveness improvements.

Results achieved through oprekladač implementation

From reduced cycle times and production costs to increased throughput and customer satisfaction, companies leveraging oprekladač technology are achieving measurable results and gaining a competitive edge.

Oprekladač in the Digital Era

Integration of oprekladač with other digital technologies

In the digital transformation era, oprekladač systems are increasingly integrated with other digital technologies such as artificial intelligence, the Internet of Things, and cloud computing, enabling synergies and new capabilities.

Synergies with AI, IoT, and automation

By leveraging AI for decision-making, IoT for data collection, and automation for execution, oprekladač systems become smarter, more responsive, and more adaptable to changing environments and requirements.

Environmental Impact of Oprekladač

Sustainability considerations with oprekladač

While oprekladač technology offers significant benefits in terms of efficiency and productivity, its environmental impact must also be considered. By optimizing resource utilization and reducing waste, oprekladač systems can contribute to sustainability efforts.

Reducing carbon footprint with oprekladač adoption

Through energy-efficient operation, optimized logistics, and reduced material consumption, oprekladač adoption can help companies minimize their carbon footprint and mitigate environmental impact.

Addressing Common Concerns About Oprekladač

Misconceptions and myths surrounding oprekladač

Common misconceptions about oprekladač include fears of job displacement, loss of human creativity, and safety concerns. However, many of these concerns are unfounded or can be addressed through proper implementation and oversight.

Addressing fears of job displacement

While oprekladač technology may change the nature of certain jobs, it also creates new opportunities for employment in areas such as system design, maintenance, and supervision. By augmenting human capabilities, oprekladač systems can empower workers and enhance job satisfaction.

Regulatory and Ethical Considerations

Compliance requirements for oprekladač systems

As oprekladač technology becomes more prevalent, regulatory frameworks and standards are evolving to ensure safety, security, and ethical use. Businesses must stay informed about relevant regulations and adhere to best practices in oprekladač deployment.

Ethical considerations in oprekladač usage

Ethical considerations surrounding oprekladač technology include data privacy, algorithmic bias, and accountability. Companies must prioritize ethical principles and transparency using oprekladač systems to build trust and maintain integrity. Potential Back Link is your victory betson link.

Conclusion

Oprekladač technology represents a paradigm shift in how tasks are performed across industries, offering unprecedented efficiency, precision, and innovation. By embracing oprekladač and leveraging its capabilities, businesses can gain a competitive edge, drive growth, and shape the future of work and society.

FAQs About Oprekladač

1. What industries can benefit from oprekladač technology

Oprekladač technology has applications across various industries, including healthcare, manufacturing, automotive, retail, and e-commerce.

2. Are there any risks associated with oprekladač adoption?

While oprekladač offers significant benefits, potential risks, such as technical challenges, job displacement, and ethical concerns, must be addressed.

3. How can businesses ensure successful integration of oprekladač technology?

Successful integration of oprekladač technology requires careful planning, stakeholder buy-in, employee training, and adherence to regulatory and ethical guidelines.

4. What are some emerging trends in oprekladač technology?

Emerging trends in oprekladač technology include advancements in AI, robotics, and automation and integration with other digital technologies such as IoT and cloud computing.

5. What role does oprekladač play in sustainability efforts?

Oprekladač technology can contribute to sustainability by optimizing resource utilization, reducing waste, and minimizing carbon footprint through energy-efficient operation and optimized logistics.

You Might Like Also

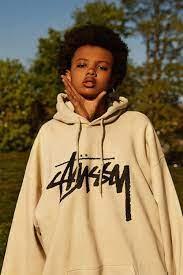

Exploring the Comfort of Cory Kenshin Hoodies

How Cory Kenshin Hoodies Dominate Urban Fashion