Stainless Steel Market Analysis, Trends, Opportunities & Challenges | 2034

February 07, 2025

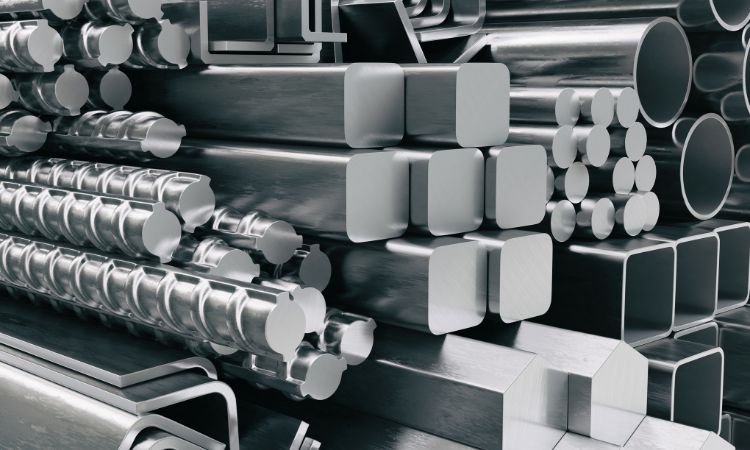

The global Stainless Steel Market Size has witnessed significant growth in recent years, reaching a value of nearly USD 153.26 billion in 2024. The market is expected to continue its upward trajectory, growing at a compound annual growth rate (CAGR) of 6.8% during the forecast period from 2025 to 2034. By 2034, the market is projected to reach a value of approximately USD 277.05 billion. Stainless steel, a versatile and corrosion-resistant material, finds widespread applications across multiple industries such as automotive, construction, aerospace, food and beverage, and healthcare. Its inherent properties, including durability, resistance to corrosion, and aesthetic appeal, make it a preferred choice for a wide range of industrial and commercial applications.

Key Benefits of Stainless Steel

Stainless steel is renowned for its many benefits, which make it indispensable in various industries:

Corrosion Resistance: The high chromium content in stainless steel provides superior resistance to corrosion, even in harsh environments. This makes it ideal for applications in industries such as construction, marine, and chemical processing.

Durability: Stainless steel has excellent tensile strength, meaning it can withstand high levels of stress and pressure. This feature is essential for structural applications, ensuring longevity and safety.

Aesthetic Appeal: The polished surface of stainless steel gives it a sleek and modern appearance, making it a popular choice for architectural and interior design applications.

Recyclability: Stainless steel is 100% recyclable, which aligns with growing global demands for environmentally friendly materials and sustainable practices. This is becoming increasingly important as industries aim to reduce their carbon footprint.

Ease of Maintenance: Stainless steel is easy to clean and maintain due to its non-porous surface, which makes it resistant to dirt, stains, and bacteria buildup. This is particularly crucial in industries such as food processing and healthcare.

Key Industry Developments

The stainless steel industry has seen several developments aimed at enhancing production techniques, improving product quality, and addressing sustainability concerns:

Advancements in Production Technology: With technological advancements such as electric arc furnaces and continuous casting, manufacturers can produce high-quality stainless steel at lower costs. These innovations are making stainless steel more accessible to a broader range of industries.

Sustainability Initiatives: The industry is increasingly focusing on sustainability, with efforts to reduce energy consumption during production processes and improve the recyclability of products. Green steel initiatives are gaining traction, with some companies committing to using hydrogen instead of traditional methods to produce steel, which could significantly reduce carbon emissions.

Global Expansion: Leading players in the stainless steel market are expanding their presence in emerging markets, particularly in Asia-Pacific, to capitalize on the growing industrialization and infrastructure development in these regions.

Strategic Mergers and Acquisitions: To enhance their product portfolios and strengthen their market position, key players in the stainless steel industry are engaging in strategic mergers and acquisitions. This is also aimed at expanding their reach to new geographies.

Driving Factors

Several factors are contributing to the growth of the stainless steel market:

Increasing Demand from Construction and Infrastructure: The rapid urbanization and expansion of infrastructure in emerging economies are driving the demand for stainless steel in construction and architecture. Stainless steel’s corrosion resistance, strength, and aesthetic appeal make it an ideal choice for both structural and decorative applications.

Growth of the Automotive Industry: Stainless steel is extensively used in the automotive sector, particularly for manufacturing exhaust systems, body panels, and fuel tanks. With the growing demand for lightweight and fuel-efficient vehicles, the automotive industry’s need for high-strength materials like stainless steel is expected to rise.

Technological Advancements in Manufacturing: New technologies in steel production, such as the development of high-performance alloys and more efficient manufacturing processes, have enhanced the appeal of stainless steel in various industrial applications.

Rising Demand for Durable and Sustainable Products: With an increasing focus on sustainability, industries are seeking durable and recyclable materials. Stainless steel, being both durable and 100% recyclable, is well-positioned to meet these demands.

Impact of COVID-19 on the Stainless Steel Market

The COVID-19 pandemic had a significant impact on global industries, including stainless steel production. The global lockdowns, disruptions in supply chains, and a slowdown in industrial activities resulted in a temporary decline in demand for stainless steel. However, the industry has since recovered and is expected to witness steady growth during the forecast period.

Several key effects of the pandemic on the stainless steel market include:

Production Delays: Many stainless steel manufacturers faced production delays due to the closure of factories and supply chain disruptions, which led to a temporary slowdown in output.

Shift in Demand: The pandemic caused a shift in demand from industrial applications to healthcare-related products, such as medical devices and personal protective equipment (PPE), driving an increased need for stainless steel in the medical sector.

Economic Recovery: As economies recover and industrial activities resume, the demand for stainless steel is expected to bounce back, especially in regions that are focusing on infrastructure development and industrial growth.

Restraining Factors

While the stainless steel market is growing, there are several factors that may hinder its growth:

High Production Costs: The production of stainless steel involves the use of high-grade raw materials, such as nickel and chromium, which are expensive. This increases the overall cost of production and may limit the affordability of stainless steel in certain applications.

Volatile Raw Material Prices: The prices of raw materials used in stainless steel production are subject to fluctuations based on global supply and demand dynamics. This volatility can make it difficult for manufacturers to predict costs accurately, which may impact their profit margins.

Environmental Concerns: The steel manufacturing process is energy-intensive and generates significant greenhouse gas emissions. Despite efforts to reduce the carbon footprint of the industry, environmental concerns may lead to increased regulatory scrutiny and higher compliance costs.

Market Segmentation

The stainless steel market can be segmented based on various factors such as type, end-use industry, and region:

By Type

Austenitic Stainless Steel: This is the most commonly used type of stainless steel, known for its excellent corrosion resistance and formability. It is used extensively in food processing, medical, and chemical industries.

Ferritic Stainless Steel: Ferritic stainless steel offers good corrosion resistance, especially in high-temperature environments, and is used in automotive exhaust systems and home appliances.

Martensitic Stainless Steel: This type is characterized by its high strength and hardness, making it suitable for manufacturing tools and machinery parts.

Duplex Stainless Steel: Offering a balance of austenitic and ferritic properties, duplex stainless steel is increasingly used in industries requiring high strength and corrosion resistance.

By End-Use Industry

- Construction and Infrastructure

- Automotive

- Aerospace

- Food and Beverage Processing

- Medical Devices

- Consumer Goods

By Region

- North America: The U.S. is a key market for stainless steel, driven by industries such as automotive, construction, and aerospace.

- Europe: Countries like Germany, Italy, and the UK are significant consumers of stainless steel, especially in the automotive and construction sectors.

- Asia-Pacific: China, India, and Japan are major contributors to the stainless steel market due to rapid industrialization and infrastructure development.

- Latin America and the Middle East & Africa: Emerging economies in these regions are witnessing a rise in demand for stainless steel as they invest in infrastructure development.

Market Outlook and Trends

The stainless steel market is poised for steady growth, driven by technological advancements, an expanding middle class in emerging markets, and increased demand for sustainable materials. Key trends to watch include:

Increased Demand for Eco-Friendly Products: As sustainability becomes a critical concern, manufacturers are focusing on producing environmentally friendly stainless steel products. This trend is likely to increase as green building certifications and eco-friendly standards become more prominent in construction and manufacturing.

Automation and Smart Manufacturing: The rise of automation and the use of AI and IoT in manufacturing processes will likely improve the efficiency of stainless steel production, reducing costs and increasing output.

Focus on Alloy Innovation: Manufacturers are developing new alloys with enhanced properties such as improved strength, heat resistance, and corrosion resistance to cater to specific industry needs.

Top Key Players in the Stainless Steel Market

- Nippon Steel Corporation

- AK Steel International B.V.

- Outokumpu Oyj

- POSCO

- Aperam SA

- Beihai Chengde Group

- JFE Steel Corporation

- Baosteel Stainless Steel Co.,Ltd

- Acerinox S.A.

- Tata Steel Limited

- Others

Opportunities and Challenges

Opportunities:

- Rising demand for stainless steel in developing countries due to industrialization.

- Increased use in the healthcare sector, especially for medical devices and surgical instruments.

- Growing focus on sustainability and eco-friendly production processes.

Challenges:

- Raw material price volatility and high production costs.

- Environmental regulations on emissions in steel manufacturing.

- Intense competition in the global market.