Predicting the lifespan of your equipment shouldn’t be based on guesswork. Understanding and calculating Mean Time Before Failure (MTBF) is crucial for improving equipment reliability and reducing costly downtime. If you're unsure how to approach it, don’t worry — this article will guide you through how to calculate MTBF from failure rate, making it easier to understand and manage the health of your assets.

What is Mean Time Before Failure (MTBF)?

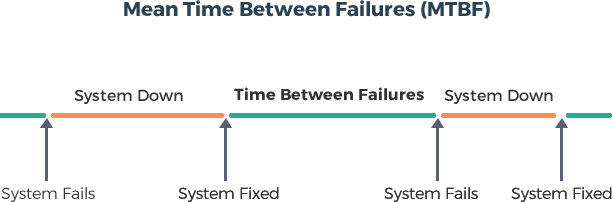

MTBF is a key metric used to predict the reliability of a system or equipment. It measures the average time that equipment operates before experiencing a failure. This calculation is particularly valuable in industries that rely heavily on machinery and equipment, such as manufacturing, utilities, and facilities management.

Instead of relying on maintenance teams to fix problems when they arise, knowing the MTBF can help in planning proactive maintenance activities, reducing unplanned downtime, and avoiding expensive repairs.

MTBF is often used in Reliability Centered Maintenance (RCM) strategies, but it’s also beneficial in any maintenance management plan aimed at improving operational efficiency.

Why is MTBF Important for Your Equipment?

Understanding the mean time before failure of your equipment provides critical insights into its performance and lifespan. Here’s why it matters:

- Proactive Maintenance: By calculating MTBF, you can predict when a machine is likely to fail and schedule maintenance before it happens. This helps prevent unexpected breakdowns.

- Optimized Operations: Knowing when to replace or repair components helps in reducing downtime and improving overall equipment efficiency.

- Cost Reduction: Proactive maintenance plans based on accurate MTBF calculations can reduce repair costs and extend the life of assets.

Calculating MTBF is the first step toward an organized maintenance strategy that prevents surprises and boosts operational efficiency.

How to Calculate MTBF from Failure Rate?

Now that we understand why MTBF is important, let’s focus on how to calculate it. The MTBF formula is straightforward and involves the following:

MTBF Formula:

MTBF= Total Operating Time/Number of Failures

Where:

- Total Operating Time is the total time the equipment has been running without failure (typically measured in hours or cycles).

- Number of Failures is the total number of failures the equipment has experienced during that period.

Example of MTBF Calculation:

Let’s say your equipment has been running for 5,000 hours and has failed 5 times during that period. The MTBF would be:

MTBF = 5000 hours/5 failures = 1000 hours

This means, on average, your equipment can operate for 1,000 hours before a failure occurs. With this information, you can better plan for replacements or preventive maintenance to avoid unexpected downtime.

How Does MTBF Help Improve Maintenance Strategy?

MTBF isn’t just a number to track; it’s a powerful tool for improving your entire maintenance strategy. Here’s how you can use MTBF to enhance your processes:

1. Predictive Maintenance

Knowing the MTBF helps you understand when equipment might fail, allowing you to schedule predictive maintenance. With predictive maintenance, you can use advanced monitoring techniques to detect wear and tear before a failure happens.

2. Optimize Resource Allocation

When you know how long equipment typically lasts between failures, you can better allocate resources for repairs, spare parts, and maintenance teams. This reduces unnecessary downtime and makes maintenance efforts more efficient.

3. Cost Control

By calculating MTBF and knowing when your equipment is likely to fail, you can plan for repairs before they become emergencies. This allows you to manage maintenance costs effectively, avoiding costly emergency fixes and ensuring that resources are used efficiently.

Common Challenges When Calculating MTBF

While calculating MTBF is relatively simple, there are some challenges businesses may face, including:

- Inconsistent Data: Without accurate data on operating hours and failures, your MTBF calculation may be unreliable.

- Complex Systems: For large-scale systems with multiple components, calculating MTBF can become more complicated, especially when failure rates vary between parts.

- Failure Data Availability: In some cases, failure data might not be readily available, making it difficult to get an accurate MTBF estimate.

These challenges are manageable with the right tools and strategies. Implementing an Enterprise Asset Management (EAM) software solution can help you track failures and operating hours, making it easier to calculate MTBF and optimize your maintenance approach.

MTBF and Preventive Maintenance

One of the main benefits of calculating mean time before failure is that it helps to design a more effective preventive maintenance program. By knowing the expected time between failures, you can implement maintenance routines that align with your equipment's needs.

Preventive maintenance activities can be scheduled around the predicted MTBF, ensuring that maintenance is done before a failure happens. This is a more efficient approach than reactive maintenance, which often leads to more costly repairs and higher downtime.

Conclusion

Don’t leave the health of your equipment to chance. By learning how to calculate MTBF from failure rate and understanding its importance, you can make more informed decisions about your maintenance strategy. Knowing when equipment is likely to fail allows you to implement proactive maintenance, reduce downtime, and save on repair costs.

Ready to improve your maintenance strategy and extend the life of your equipment? Start calculating MTBF today with MicroMain's EAM software and get your operations running more efficiently.

Stop guessing your equipment lifespan. Learn how to calculate mean time before failure (MTBF) and improve your maintenance strategy today with MicroMain's advanced asset management solutions.