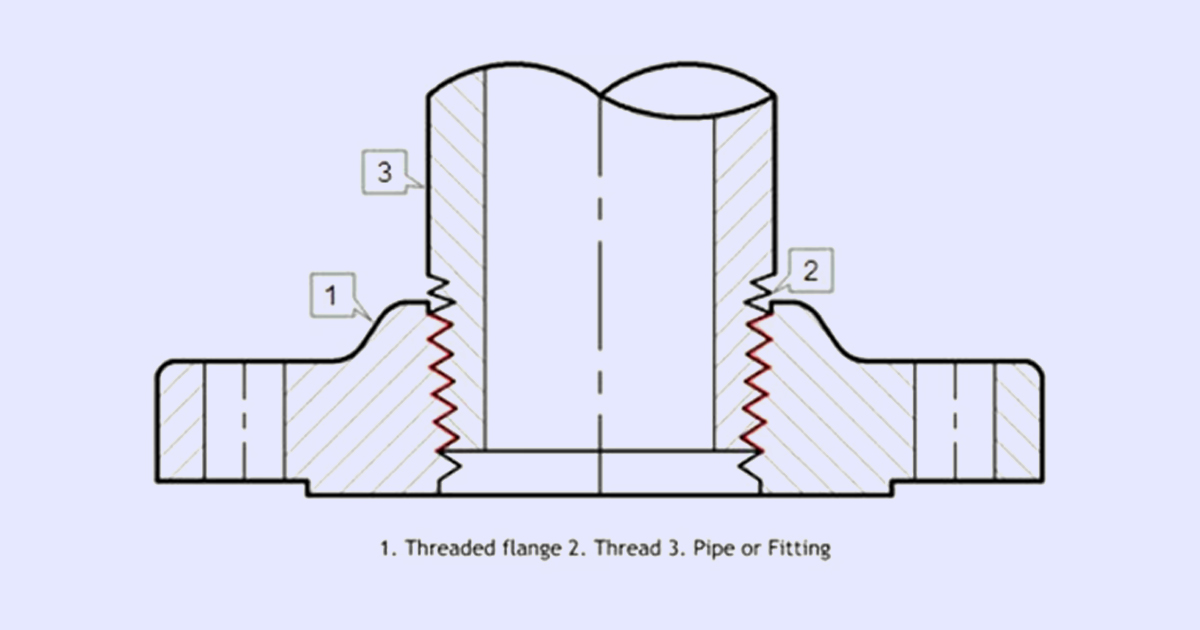

Threaded flanges, also known as screwed flanges, are a type of pipe flange that has a threaded bore, allowing it to be screwed onto a pipe without the need for welding. These flanges are ideal for applications where welding is impractical or hazardous.

Key Features of Threaded Flanges

🔹 Threaded Bore – Designed with internal threads that allow it to be screwed onto externally threaded pipes without welding.

🔹 Material Variety – Available in carbon steel, stainless steel, alloy steel, and other specialized materials for different applications.

🔹 Standard Compliance – Manufactured according to industry standards such as ASME B16.5, ANSI, and DIN.

🔹 Pressure Ratings – Suitable for low to moderate pressure applications, typically up to Class 600.

🔹 Size Availability – Commonly available in small pipe diameters (typically ½" to 4").

🔹 Easy Installation & Removal – Can be installed and removed easily without special tools or welding, making it convenient for maintenance and temporary piping systems.

🔹 Corrosion Resistance – Threaded flanges made from stainless steel and other alloys offer resistance to rust and chemical corrosion.

Advantages of Threaded Flanges

No Welding Required – Threaded flanges can be installed without welding, making them ideal for applications where welding is impractical or hazardous.

Easy Installation & Removal – Since they screw onto the pipe, they allow for quick assembly and disassembly, making maintenance easier.

Cost-Effective – Reduces labor and installation costs by eliminating the need for welding equipment and skilled welders.

Ideal for High-Risk Environments – Suitable for flammable or explosive environments (e.g., oil & gas industries) where welding could pose a fire hazard.

Reusable – Threaded flanges can be removed and reused, making them a great option for temporary or frequently modified piping systems.

Suitable for Small Pipe Sizes – Specifically designed for small-diameter pipes, usually up to 4 inches.

Compatible with High-Temperature Alloys – Available in various materials such as stainless steel and special alloys, making them suitable for high-temperature and corrosive environments.

Conclusion

Threaded flanges are a reliable and cost-effective solution for low-pressure and small-diameter piping systems. Their ability to be installed without welding makes them ideal for hazardous environments where welding poses a risk. They offer easy installation, reusability, and compatibility with various materials, making them a preferred choice in industries like oil & gas, petrochemicals, and water supply.

However, they are not suitable for high-pressure or high-vibration applications due to the potential risk of leakage. Despite this limitation, threaded flanges remain a practical option for systems requiring frequent maintenance or temporary installations.

By choosing the right material and ensuring proper sealing, threaded flanges can provide a durable and efficient connection in various industrial applications.