Understanding CNC Machining Parts and Their Importance

August 22, 2025

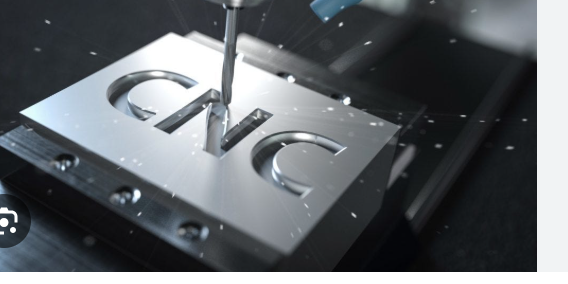

Introduction to CNC Machining Parts

CNC machining parts play a vital role in modern manufacturing industries. These components are produced using computer numerical control systems, which allow precise shaping, cutting, and drilling of materials. The accuracy offered by CNC machining parts ensures consistency and efficiency in industrial production.

Common Materials Used for CNC Machining Parts

Choosing the right material is crucial for the performance of cnc machining parts. Metals like aluminum, stainless steel, brass, and titanium are widely used due to their durability and strength. Plastics and high-performance polymers are also popular when lightweight or corrosion-resistant components are required. Material selection influences the longevity, strength, and application suitability of the parts.

Advantages of CNC Machining Parts

High Precision and Accuracy

CNC machining parts are known for their precision. Machines follow programmed instructions that result in highly accurate dimensions, making these components suitable for applications that demand tight tolerances.

Consistent Quality

Unlike manual production, cnc machining parts maintain uniform quality across multiple units. This consistency is essential in industries such as aerospace, automotive, and medical devices.

Complex Designs

CNC machining allows the creation of intricate and complex designs that would be difficult to achieve with conventional methods. Components can feature unique shapes, detailed threads, or internal cavities without compromising precision.

Reduced Production Time

Automation and programmed operations reduce production time significantly. CNC machines can operate continuously, increasing output while minimizing human error.

Applications Across Industries

Automotive Industry

CNC machining parts are widely used in engines, gear systems, braking components, and suspension assemblies. Their precise manufacturing ensures vehicle performance, reliability, and safety.

Aerospace Industry

High-performance cnc machining parts are crucial in aerospace for producing turbine blades, landing gear, and structural components. Tolerance and durability are critical due to the extreme conditions these parts face.

Medical Industry

Medical devices such as implants, surgical instruments, and diagnostic equipment rely on cnc machining parts. Accuracy and regulatory compliance are essential for ensuring patient safety.

Electronics and Technology

CNC machining parts are also used in electronic devices, enclosures, and precision mechanical assemblies. Quality components improve device reliability and lifespan.

Key Considerations for Selecting CNC Machining Parts

Supplier Expertise

Working with experienced suppliers ensures that CNC machining parts meet design specifications and industry standards. Skilled engineers help in material selection, design optimization, and problem-solving.

Advanced Machinery

Suppliers equipped with multi-axis CNC machines can produce complex parts efficiently. The latest technology guarantees precise dimensions and high-quality finishes.

Quality Control

Regular inspections, testing, and measurement procedures ensure cnc machining parts maintain high standards. Quality control is vital to prevent defects and maintain reliability.

Communication and Collaboration

Clear communication between clients and manufacturers ensures that designs, adjustments, and timelines are managed effectively. Collaboration improves production efficiency and ensures the final parts meet requirements.

Emerging Trends in CNC Machining Parts

Automation and Robotics

The integration of automation in CNC machining improves production speed, reduces errors, and ensures continuous operation. Robotic arms and automated handling enhance efficiency and precision.

Hybrid Manufacturing

Combining additive manufacturing with traditional CNC machining allows the creation of complex geometries while maintaining accuracy. Hybrid techniques reduce waste and support innovative designs.

Sustainable Manufacturing

Eco-friendly materials and energy-efficient machines are increasingly used in producing cnc machining parts. Sustainable practices reduce environmental impact without compromising quality.

Digital Simulation and Modeling

Digital simulation tools allow engineers to test designs virtually before production. This process reduces errors, optimizes materials, and ensures parts perform as intended in real applications.

Challenges and Solutions

Tool Wear and Maintenance

CNC machines experience tool wear over time, which can affect precision. Regular maintenance and timely replacement of tools ensure cnc machining parts maintain their quality.

Design Complexity

Highly intricate designs require skilled programming and advanced machinery. Collaboration with experienced engineers ensures accurate production of complex cnc machining parts.

Handling and Storage

Proper handling and storage are crucial to prevent damage or dimensional changes. Correct procedures maintain surface finish, dimensions, and overall quality.

Future Outlook of CNC Machining Parts

CNC machining parts will continue to be essential in manufacturing. Advancements in automation, artificial intelligence, hybrid manufacturing, and material science will improve efficiency, precision, and cost-effectiveness. New applications and innovations will expand their use across industries, making cnc machining parts indispensable for modern production.

Conclusion

CNC machining parts are fundamental to the success of modern manufacturing. They provide precision, consistency, and versatility required in industries ranging from automotive to medical devices. By choosing the right materials, working with expert suppliers, and embracing advanced technology, manufacturers can produce high-quality cnc machining parts that meet industry standards and support innovation.