Understanding the Importance of Hydrogen Detection in Modern Technology

August 13, 2025

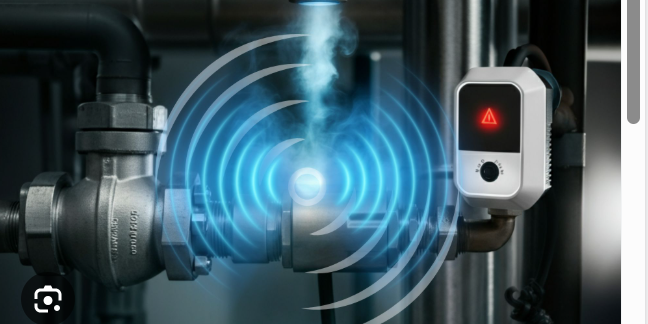

As the world moves toward cleaner and more sustainable energy sources, hydrogen is gaining significant attention due to its potential as a green fuel. However, hydrogen is highly flammable and requires careful monitoring to ensure safety. This is where hydrogen detection technology plays a crucial role. Understanding the principles, applications, and advancements of hydrogen detection is essential for industries aiming to utilize hydrogen safely.

What Is Hydrogen Detection?

Hydrogen detection refers to the process and technology used to identify the presence of hydrogen gas in the environment. Since hydrogen is colorless, odorless, and highly flammable, specialized sensors and detection systems are necessary to monitor its levels and prevent dangerous situations.

Why Is Hydrogen Detection Necessary?

Hydrogen’s unique properties pose both opportunities and risks. It burns quickly and can ignite at low concentrations in air, making leaks hazardous. Detecting hydrogen early can prevent fires, explosions, and equipment damage, especially in industries where hydrogen is produced, stored, or used.

Key industries requiring reliable hydrogen detection include:

- Energy production and storage

- Chemical manufacturing

- Automotive sector, especially hydrogen fuel cell vehicles

- Aerospace and research laboratories

Without effective detection systems, accidental leaks could lead to catastrophic incidents.

Technologies Used for Hydrogen Detection

Various types of sensors and detection methods are employed to identify hydrogen gas. Each has specific benefits and applications depending on the environment and sensitivity requirements.

Electrochemical Sensors

Electrochemical sensors operate by producing an electrical current when hydrogen gas interacts with the sensor’s electrode. These sensors are widely used due to their sensitivity and accuracy. They are especially suitable for indoor or controlled environments.

Catalytic Sensors

Catalytic sensors detect combustible gases by oxidizing hydrogen on a heated catalyst, causing a change in resistance or temperature. They are effective for detecting a wide range of flammable gases but require oxygen to function properly.

Semiconductor Sensors

These sensors change their electrical conductivity when exposed to hydrogen gas. Semiconductor sensors are cost-effective and compact but may be affected by humidity and other gases.

Optical Sensors

Optical hydrogen detectors use light absorption or refractive index changes to detect hydrogen. They offer fast response times and can operate in explosive environments without ignition risks.

Thermal Conductivity Sensors

Hydrogen’s thermal conductivity differs significantly from air, and these sensors detect changes in heat transfer properties caused by hydrogen presence.

Applications of Hydrogen Detection Systems

Hydrogen detection is critical in many sectors to ensure safety and regulatory compliance.

Hydrogen Fuel Stations

With the rise of hydrogen-powered vehicles, refueling stations require continuous hydrogen monitoring to avoid leaks during storage and dispensing.

Industrial Plants

Chemical and petrochemical industries often use hydrogen in production processes. Detectors help identify leaks in pipelines, reactors, and storage tanks.

Laboratories and Research Facilities

Research involving hydrogen requires strict safety protocols supported by effective detection to avoid accidental exposure.

Renewable Energy Storage

Hydrogen produced by electrolysis as a storage medium for renewable energy necessitates monitoring to prevent hazards during storage and transport.

Choosing the Right Hydrogen Detection System

Selecting a suitable hydrogen detection system depends on various factors such as:

- Sensitivity: The sensor should detect hydrogen concentrations below the lower explosive limit (4% in air).

- Response time: Rapid detection allows timely intervention.

- Operating environment: Temperature, humidity, and presence of other gases affect sensor choice.

- Power requirements: Battery-operated or mains-powered systems may be needed depending on the site.

- Maintenance needs: Ease of calibration and servicing enhances long-term reliability.

- Safety certifications: Devices must comply with industry safety standards.

Challenges in Hydrogen Detection

Despite advances, hydrogen detection faces some challenges:

- False alarms: Cross-sensitivity to other gases may cause incorrect alerts.

- Sensor degradation: Long-term exposure to harsh environments can reduce sensor accuracy.

- Installation complexity: Proper placement is essential for effective detection.

- Cost: High-performance sensors may be expensive, affecting large-scale deployment.

Addressing these issues requires careful planning, regular maintenance, and updated technologies.

Recent Advances in Hydrogen Detection

Technology improvements are enhancing the capabilities of hydrogen detection systems.

- Wireless monitoring allows real-time data collection and remote management.

- Smart sensors integrate with IoT platforms for predictive maintenance and analytics.

- Nanotechnology-based sensors increase sensitivity and selectivity.

- Explosion-proof and intrinsically safe devices improve operational safety in hazardous locations.

These innovations are making hydrogen detection more reliable and user-friendly.

Best Practices for Implementing Hydrogen Detection

To maximize safety and efficiency, organizations should follow key guidelines:

- Conduct a thorough risk assessment to identify potential leak points.

- Install detectors at strategic locations such as near valves, joints, and storage tanks.

- Perform regular testing and calibration to ensure sensor accuracy.

- Train staff to respond appropriately to alarms.

- Integrate detection systems with emergency shutoffs and ventilation controls.

Conclusion

hydrogen detection is a fundamental aspect of modern technology focused on sustainable energy and industrial safety. As hydrogen use expands globally, deploying effective detection systems becomes even more critical. By understanding different sensor technologies, applications, and challenges, industries can better manage risks and harness hydrogen’s benefits safely.