The FRP Security Cabin is a small vertically oriented cuboidal container suitable for construction sites and other commercial structures. It is normally found at the entry gates and is frequently utilized by security personnel. For further strength and sturdiness, the walls are made of fiber-reinforced polymers, and the corners are reinforced with mild steel. It has sliding-type glass windows on both sides of the walls and a totally closed top.

FRP Security Cabins are a type of cabin that is commonly used in the building of security cabins, portable offices for construction sites, and so on. The FRP material is largely used because of its excellent insulating properties. These cabins are simple to maintain, require no maintenance or pointing and have concealed wiring.

What Exactly Is FRP Cabin?

FRP (Fibre Reinforced Plastic) cabins are another type of cabin that is commonly used for building security cabins, temporary offices for use on construction sites, and other similar uses. The fiberglass reinforced plastic (FRP) material is widely used due to its superior insulating characteristics. Upkeep is minimal because there is no need for painting or upkeep, and the wiring is concealed within the walls of the cabin.

FRP (Fibreglass Reinforced Plastics, often known as GRP or Glass Reinforced Plastics) is a contemporary composite material used in security cabin construction. Because of its simplicity of application and unique physical properties, FRP has become one of the most preferred solutions for rehabilitating concrete structures.

FRP utilized in security cabins is a relatively new class of non-corrosive, high strength, lightweight material that has developed as a feasible material for a variety of structural engineering applications in the last 15 years.

Advantages of FRP Security Cabins

The inherent corrosion resistance of fiberglass-reinforced polymers (FRP) is perhaps the most compelling justification for utilizing them. In many circumstances, they are the only materials capable of handling a certain service environment; in others, their corrosion resistance is paired with their cost-effectiveness to make them the most cost-effectively acceptable choice. FRP corrosion resistance is determined by both the resin quantity and the individual resin utilized in the laminate. In general, the higher the resin concentration, the stronger the corrosion resistance of the laminate.

1. Weight Advantages

FRP also has a low weight-to-strength ratio, which is a noteworthy advantage. FRP will typically weigh one-seventh the weight of steel and half the weight of aluminum for the same strength. Lightweight qualities are significant when it comes to cost and convenience of installation, particularly for pipes and tanks. When equipment must be mounted on existing structures, such as scrubbers on mezzanines or rooftops, and for specialised applications such as FRP tank trailers, the inherent lightweight of FRP is advantageous.

2. High Strength

While not as crucial for corrosion-resistant equipment, high strength is critical in the design of FRP equipment for applications such as missiles, pultruded shapes, and so on. The great strength of filament wound pipe and duct provides the lightweight characteristics stated before.

3. Economy

The affordable cost of FRP is frequently cited as a significant advantage. When comparing corrosion-resistant materials, rubber lining, titanium, Monel, Hastelloy, Carpenter 20, and exotic stainless materials are widely used as alternatives to FRP. In many circumstances, FRP may provide both a satisfying answer to corrosion problems and the most cost-effective alternative. There is no general rule for comparing the costs of FRP to other materials. These costs are determined by the application, the design considerations, the pressures (or vacuums) involved, the product configurations, and the cost and availability of raw materials.

4. Flexibility

Too many people disregard FRP's adaptability. It is ideal for many applications because it allows you to achieve things that other materials do not allow you to perform inexpensively. You can mold practically any configuration or piece of equipment for which a temporary or permanent mold may be built. For ducting, for example, you can create all types of elbows, rectangular to circular transitions, Tee inlets, and flanges in a broad variety of round and rectangular sizes and forms for a low tooling cost. FRP can also be used to line existing constructions.

Stunning Features of FRP Security Cabin

• Excellent tolerability, corrosion resistance, and durability

• Aesthetically designed – no need for a finishing touch

• Lightweight and long-lasting

• Extremely resistant to natural calamities and weatherproof

• Lightweight and simple to erect.

• Easy to maintain.

• No foundation is required for the movable cabins.

• All electrical amenities, such as wiring, sockets, and light fixtures, are present.

• Adequate insulation of movable building cabins maintains a temperature of 5-7oC in the atmosphere

Why Choose FRP Portable Security Cabin?

FRP or Portable Security Cabin is built of high-quality raw materials that are lightweight and easy to transport; even when manufactured as assembled, they can be readily transported anyplace you want. FRP security cabins manufacturers focus on assembling and manufacturing the product with authentic quality and natural management. These security cabins are installed at businesses, hotels, construction sites, residential organizations, training facilities, and restaurants, among other places. These constructed security cabins are very easy to position and install for transportation to various fields, resistant to unforgiving climate, even if robust construction. The following facts will convince you that a FRP security cabin for your worksite is a must:

• These are beautifully planned and do not require any further finishing designs.

• Satisfactory storage building protection, as well as cabins that serve to regulate internal temperature with proper insulation

• Weatherproof

• There are several electrical amenities available, such as wiring, lights, sockets, and so on.

• Does not necessitate the foundation of a business.

• Exceptional protection from natural disasters or occurrences

What Is the Cost of FRP Security Cabin?

FRP security cabins are available in a variety of sizes and construction styles. As a result, the FRP Security Cabins price varies appropriately. The prices start at 30,000 INR and go up to 2 Lakh INR. These security cabins are in high demand throughout the market due to qualities like as weather resistance, a durable finish, high strength, a compact design, and a gorgeous pattern. Nonetheless, if you locate a FRP security cabin of great quality and corrosive resistance, the price is irrelevant.

So, in general, the price of a security cabin you're searching for starts around 30,000 INR per unit and can go up to a lakh or more depending on the type of portable cabin, product quality, brand, and so on.

Conclusion

FRP Security Cabins are a great way to add extra space to residential and business buildings. They take less time to build, come in a variety of shapes and sizes, and can be easily moved from one location to another. These security cabins are both strong and light. When it comes to benefits, FRP security cabins are in high demand in a variety of business and residential structures. They serve as a little resting area for security staff or watchmen. These movable security guard booths are sometimes utilized as ticketing counters. They are shielded from noise and the elements.

Do you have any further advantages over the use of FRP Security Cabins?

You Might Like Also

Ultimate FAQ Guide of Vibro Sifter Machine

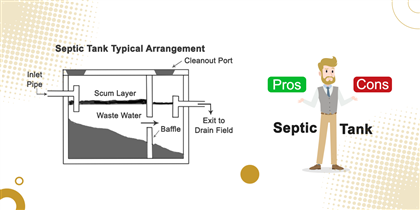

The Working Principle of Septic Tank and Its Pros & Cons