Aerospace Composites Market Advancing Lightweight Strength for Next-Generation Aircraft Engineering

December 10, 2025

Introduction

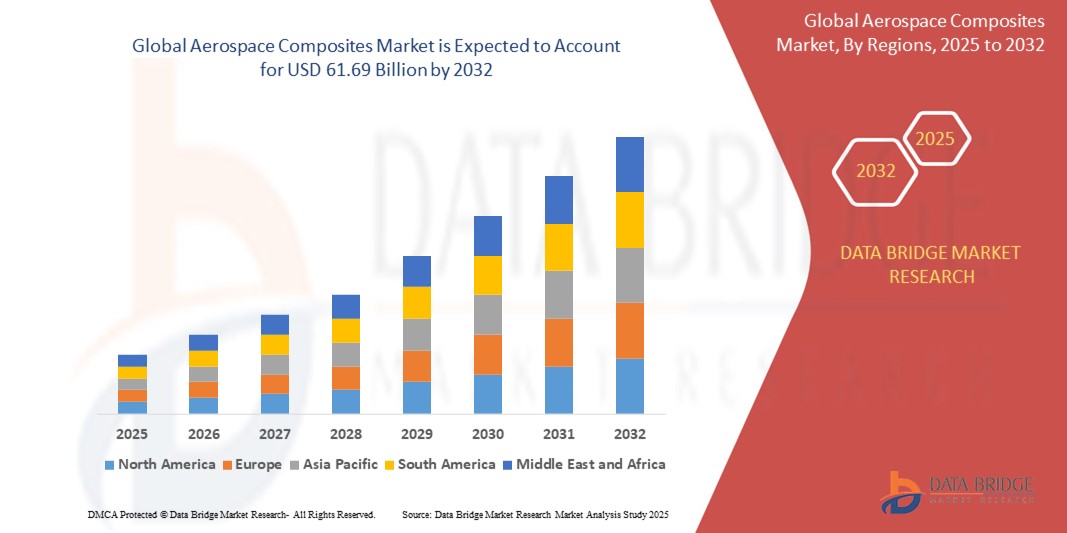

The Aerospace Composites Market is expanding rapidly as aircraft manufacturers increasingly adopt lightweight and high-strength materials to enhance performance, fuel efficiency, and safety. Aerospace composites—made from carbon fiber, glass fiber, aramid, and advanced resins—offer superior durability, corrosion resistance, and weight reduction compared to traditional metals. As global air travel demand rises and aerospace companies pursue greener aviation solutions, composite materials have become central to modern aircraft design.

Market Size and Growth Projections

The market is witnessing robust growth fueled by fleet modernization programs, increasing commercial aircraft deliveries, and the surge in next-generation defense aircraft. Composites are becoming essential for aircraft structures such as wings, fuselage sections, interior panels, nacelles, and rotor blades. With continuous innovation in resin systems, automated manufacturing, and thermoplastic composites, the industry is expected to grow steadily as aviation shifts toward higher efficiency and aerodynamic performance.

Get More Details : https://www.databridgemarketresearch.com/reports/global-aerospace-composites-market

Key Growth Factors

Rising demand for lightweight, fuel-efficient aircraft

Increased production of commercial and defense aircraft

Advancements in carbon fiber and resin matrix technologies

Expansion of electric and hybrid-electric aircraft requiring lightweight structures

Growing use of composites in UAVs, helicopters, and space systems

Strengthening focus on sustainable aviation and emission reduction

Increasing investments in automation and advanced manufacturing technologies

Market Segmentation

By Fiber Type

Carbon Fiber Composites

Glass Fiber Composites

Aramid Fiber Composites

Ceramic Matrix Composites

Hybrid Fiber Composites

By Resin Type

Epoxy Resin

Polyester Resin

Phenolic Resin

Thermoplastic Resin

Polyimides

Cyanate Ester Resin

By Application

Interior Components

Exterior Components

Structural Applications

Engine Components

Aircraft Seats

Nacelles & Radomes

By Aircraft Type

Commercial Aircraft

Military Aircraft

General Aviation

Helicopters

UAVs

Spacecraft

By Manufacturing Process

Hand Lay-Up

Automated Fiber Placement (AFP)

Filament Winding

Resin Transfer Molding (RTM)

Compression Molding

Additive Manufacturing

Regional Insights

North America

A dominant region led by the presence of major aerospace OEMs, strong defense spending, and advanced composite manufacturing infrastructure. The U.S. continues to lead innovation in carbon-fiber-reinforced composites.

Europe

Europe holds a major share due to Airbus production, stringent emission targets, and extensive R&D in lightweight aviation technologies. Germany, France, and the UK are central to composite innovation.

Asia-Pacific

APAC is the fastest-growing region as China, India, and Japan scale up aircraft production, invest in aerospace research, and expand their MRO and defense sectors.

Middle East & Africa

Growth in MEA is supported by rising aircraft procurement, expanding MRO capabilities, and strong aviation activity in countries like UAE, Saudi Arabia, and Qatar.

South America

Brazil, led by Embraer, plays a significant role in regional aircraft production, contributing to rising composite material demand.

Key Market Drivers

Surging global air travel and commercial aircraft deliveries

Demand for high-performance materials reducing aircraft operational costs

Growing adoption of composite materials in next-generation defense programs

Increasing preference for corrosion-resistant and fatigue-resistant materials

Development of thermoplastic composites for faster production

Rising use in space exploration missions and satellite structures

Growing demand for lightweight components in electric aircraft

Market Challenges and Restraints

High manufacturing and raw material costs

Complex production processes requiring specialized equipment

Recycling and sustainability challenges for composite waste

Long certification cycles in aerospace applications

Dependence on limited suppliers for advanced carbon fibers

Skilled labor shortages in composite engineering

Competitive Landscape and Key Companies

Hexcel Corporation

Toray Industries

SGL Carbon

Solvay

Teijin Limited

Mitsubishi Chemical Group

Gurit Holding AG

Owens Corning

DuPont

Honeywell International

Collins Aerospace

Companies are focusing on automation, high-performance fiber development, sustainable composite solutions, and expanding production capabilities.

Technological Innovations

Next-generation thermoplastic composites enabling faster, recyclable production

Automated fiber placement (AFP) and advanced robotics improving precision

Nano-enhanced resins offering higher strength-to-weight performance

Additive manufacturing of composite components

High-temperature ceramic matrix composites for engine components

Digital twin technology for structural simulation and lifecycle optimization

SWOT Analysis

| Strengths | Weaknesses |

|---|---|

| Lightweight, high-strength, corrosion-resistant materials | High manufacturing and raw material costs |

| Essential for modern aircraft performance | Complex certification and production requirements |

| Wide application across commercial, military, and space sectors | Limited recyclability |

| Opportunities | Threats |

|---|---|

| Growing demand for next-generation electric and hybrid aircraft | Fluctuations in carbon fiber and resin supply |

| Expansion of UAVs, defense programs, and space missions | Competition from metal alloys and emerging materials |

| Increasing automated manufacturing and digitalization | Regulatory and environmental concerns |

Future Market Outlook

The Aerospace Composites Market is expected to grow steadily as aviation transitions toward sustainable, lightweight, and high-efficiency technologies. Increasing production rates of commercial aircraft, expansion of the UAV sector, and breakthrough innovations in thermoplastic and ceramic composites will fuel long-term market evolution. As aerospace manufacturers prioritize fuel savings, structural optimization, and reduced emissions, composite materials will remain essential across all next-generation aircraft platforms.

Conclusion

The Aerospace Composites Market is set for sustained growth driven by rising aircraft production, demand for lightweight materials, and advancements in composite technologies. With expanding applications in commercial, military, and space aviation, the market will continue to evolve as an indispensable component of global aerospace innovation.

Get More Reports :

https://www.databridgemarketresearch.com/reports/global-analytics-market

https://www.databridgemarketresearch.com/reports/global-women-nutrition-market

https://www.databridgemarketresearch.com/reports/global-biscuits-packaging-market

https://www.databridgemarketresearch.com/reports/global-dementia-treatment-market

https://www.databridgemarketresearch.com/reports/global-middle-east-respiratory-syndrome-mers-market