Cutting materials is a big part of making things in factories. There are many ways to cut, but two popular methods are laser cutting machines and traditional cutting tools. At WEILI, we work with both, but we often see the laser cutting machines giving results that surprise many people. Traditional cutting, like using saws or blades, has been around for a long time. It works well for some jobs but sometimes leaves rough edges or wastes material. Laser cutting machines use a focused light beam that melts or burns the material with great accuracy. This difference means the two methods can change how a product looks and how fast it gets made. Let’s talk more about why laser cutting machines can improve product quality and how to decide which method to choose, especially when lots of items need cutting.

How Laser Cutting Machines Improve Product Quality Compared to Traditional Cutting

When you use a laser cutting machine, the light beam is so thin and exact that it cuts very cleanly. The edges are smooth and neat, so products look better without needing extra work to fix rough spots. Traditional cutting tools, like saws or shears, can leave jagged edges or small cracks. For example, when cutting metal, a laser cuts through with little heat damage around the edges, while traditional blades might bend the metal or cause small dents. This means less waste and fewer mistakes. Also, laser cutting can handle very small and detailed shapes that traditional tools can’t do well. Imagine trying to cut tiny letters or complex patterns with a blade—that’s tough and slow. WEILI’s laser machines can do these tasks quickly and exactly every time. Sometimes, though, laser cutting can cause slight discoloration on some materials because of the heat, but it is often easy to clean or avoid by adjusting settings. Traditional tools don’t have this heat issue but can’t match the precision. From my experience at WEILI, clients who switch to laser cutting notice how their products look more professional and consistent. Sometimes, traditional cutting machines wear down and need sharpening, causing uneven cuts, but laser machines keep the same quality over long runs. This can save time and money by reducing quality checks and fixes. In short, laser cutting often means better products even if it costs a little more upfront.

How to Choose Between Laser Cutting Machines and Traditional Cutting for Bulk Orders

Picking the right cutting method for big orders depends on many things. At WEILI, we always talk with customers about what they really need. If the order needs simple shapes and the materials are thick or hard, traditional cutting sometimes works fine and is less expensive. For example, cutting large steel plates for construction can be fast with big saws. But when the order requires many detailed pieces or fine edges, laser cutting machines can finish faster and with fewer mistakes. The faster speed helps when thousands of pieces are needed, because laser cutting machines can run continuously and change designs without stopping. Traditional cutting tools usually need manual changes or blade swaps that slow work down. Another thing is material waste. Laser cutting is very good at using almost all the material, arranging cuts close together. This saves money, especially for costly metals or plastics. Traditional cutting often wastes more because the blade width or tool shape forces wider gaps. Sometimes, the choice depends on your budget and delivery time. Bulk orders with tight deadlines might get better results from laser cutting because the machines are automated and precise, reducing rework time. But if the budget is low and the design is simple, traditional cutting might be the way to go. At WEILI, we consider all these points and suggest the best fit. Sometimes, mixing both methods helps—laser for detailed parts and traditional for simple cuts. This hybrid way can save money and still keep quality high. It’s about knowing what works best for each job, not just following one method blindly. When you choose right, the whole process is smoother, and customers get what they want on time.

What Common Issues Are Solved by Laser Cutting Machines That Traditional Methods Can’t Handle?

Cutting materials is a very important step in making many products. For a long time, people used traditional cutting tools like saws, knives, and shears. These tools work well but have some problems that can slow down work or cause mistakes. That is why laser cutting machines, like those made by WEILI, are becoming popular. Laser cutting uses a strong beam of light to cut through materials. This way of cutting solves many problems that traditional tools cannot fix.

One big problem with traditional cutting is that it can be slow and not very accurate. When using saws or knives, it is easy to make small mistakes, and the edges can be rough or uneven. Sometimes, the material can get damaged, especially if it is soft or thin. Laser cutting machines can cut very fast and with great precision. They leave clean edges with no roughness, so the product looks better and needs less fixing afterward.

Another issue is that traditional methods cannot cut very complex shapes easily. If you want to make detailed designs or small patterns, using hand tools can be very hard and take a long time. Laser cutting machines can easily follow detailed designs made on a computer. This means they can cut very small, detailed, or complicated shapes quickly and perfectly.

Traditional cutting tools also wear out quickly and need to be replaced or sharpened often. This can cost money and slow down work. Laser cutting machines do not have blades that wear out because they use light to cut. This makes them last longer and saves money in the long run.

Finally, cutting by hand or with old tools can be dangerous. People can get hurt by sharp tools or machines. Laser cutting machines are safer because they are controlled by computers, and the cutting happens inside a closed space. This helps protect workers from accidents.

In short, WEILI laser cutting machines solve many problems like slow cutting, rough edges, difficulty in cutting complex shapes, tool wear, and safety risks. These benefits make laser cutting a better choice for many businesses today.

Where Can Wholesale Buyers Get the Most Cost-Effective Laser Cutting Solutions?

Buying laser cutting machines can be a big decision for businesses, especially for wholesale buyers who need many parts or products made quickly and cheaply. Wholesale buyers want to find laser cutting solutions that save money but still give good quality. WEILI offers some of the best laser cutting machines and services to help wholesale buyers get the most cost-effective solutions.

One way to save money is by getting machines that work fast and use energy efficiently. WEILI laser cutting machines are designed to cut materials quickly, which means more pieces can be made in less time. This saves money on labor and helps meet large orders faster. Also, these machines use less power compared to older machines, which lowers electricity bills.

Wholesale buyers can also save money by choosing machines that can cut many types of materials. WEILI machines can cut metal, wood, plastic, and fabric. This means buyers do not need to buy different machines for different jobs. Having one machine that does many jobs saves space and money.

Another important factor is maintenance cost. Machines that break down often can cost a lot to fix and cause delays. WEILI laser cutting machines are built with strong parts and smart technology that needs less fixing. This helps wholesale buyers avoid expensive repairs and keeps production running smoothly.

Wholesale buyers should also look for good customer support and training. WEILI provides helpful guides, training, and fast help when needed. This support helps buyers use the machines better and avoid mistakes that could waste materials or time.

Finally, buying in bulk or choosing the right machine size for the job can lower costs. WEILI offers different models, so wholesale buyers can pick machines that fit their needs without paying for extra features they don’t need.

wholesale buyers can find cost-effective laser cutting solutions by choosing fast, energy-saving, multi-material machines with low maintenance from WEILI. Good customer support and picking the right machine size also help save money while keeping quality high.

What Are the Trending Applications of Laser Cutting Machines Versus Traditional Cutting in Industry?

Industries all over the world are always looking for better ways to make products. Laser cutting machines, like those from WEILI, are becoming popular in many industries because they offer new and better ways to cut materials. While traditional cutting methods are still used in some places, laser cutting is trending because it can do many things that old tools cannot.

One trending application is in the fashion and textile industry. Traditional cutting of fabric by hand or with simple machines can be slow and cause uneven pieces. WEILI laser cutting machines can cut fabric quickly and with perfect shapes. They can also cut delicate materials without causing damage. This helps clothing makers create new styles faster and with less waste.

In the electronics Laser blanking line industry, parts need to be very small and precise. Traditional cutting methods cannot make tiny, detailed cuts easily. Laser cutting machines can cut circuit boards and other small parts with very high accuracy. This helps make better and smaller electronic devices.

The automotive industry also uses laser cutting more and more. Car parts need to be strong and exact. Laser cutting machines can cut metal parts with clean edges and perfect shapes. This means cars can be made safer and more reliable. Traditional cutting methods may leave rough edges that need extra work.

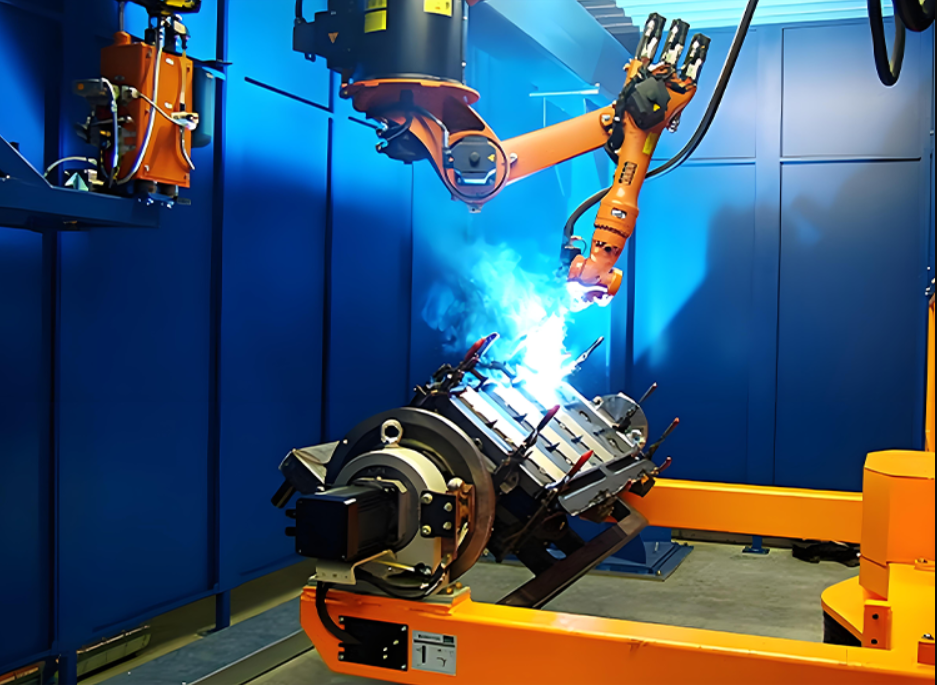

Another new use is in art and decoration. Artists and designers use WEILI laser cutting machines to make detailed designs in wood, metal, or plastic. Traditional methods make it hard to create Laser welding/cleaning machine delicate patterns, but laser cutting can make beautiful and complex shapes easily.

Finally, laser cutting is popular in making signs and packaging. Laser cutting helps create neat letters and designs quickly. This is harder to do with old cutting tools.

In summary, laser cutting machines are changing many industries by offering faster, more precise, and more flexible cutting. WEILI’s machines help industries like fashion, electronics, automotive, art, and packaging do things that traditional cutting cannot do as well. This is why laser cutting is a big trend in today’s world.

You Might Like Also

Flexo Printer Slotter Machine: Eco-Friendly Printing

Flexo Printer Slotter Machine: Eco-Friendly Printing

Carbon Fibre Electric Wheelchairs Travel With Less Effort

New Developments in Pipe End Beveling Machine Technology

Beverage Machinery Designed to Handle Multiple Bottle Sizes With Ease