Why Transparency Is the New Gold Standard in Liposomal Manufacturing

January 25, 2026

Imagine buying a used car, but the dealer forbids you from looking under the hood. You just have to "trust" that the engine runs. Sounds ridiculous, right? You wouldn't hand over your cash without some proof that the thing actually works.

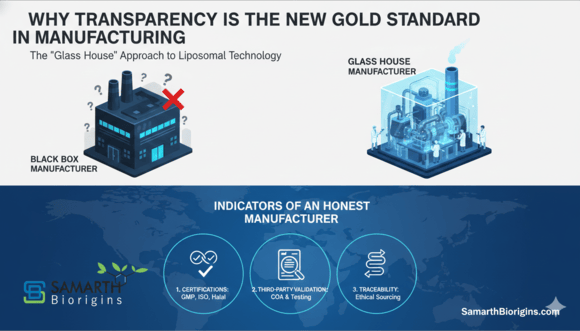

Yet, in the supplement industry, brands often buy ingredients from "black box" manufacturers where the process is a total mystery. Ingredients go in, a product comes out, and nobody really knows what happened in between.

For a long time, this was just how business worked. But the tide is turning. With major marketplaces like Amazon tightening their grip—requiring third-party cGMP verification for all supplements by 2026—that black box is quickly becoming a liability.

At Samarth Biorigins, we believe the future of manufacturing looks less like a fortress and more like a glass house. Here is why transparency is the only currency that matters in the liposomal space.

What Are Liposomes, Anyway? (And Why Do They Need Protection?)

Before we dig into the paperwork, let’s talk about the tech.

Think of a standard vitamin C capsule like a letter sent in the mail without an envelope. It might get there, but it’s going to get battered by the elements—rain, wind, and rough handling—along the way. In your body, those elements are harsh stomach acids and digestive enzymes that destroy nutrients before they ever reach your bloodstream.

Liposomal technology is the envelope.

It wraps the nutrient in a microscopic layer of fat (phospholipids). This protective bubble acts like a VIP escort, shielding the nutrient from digestion and delivering it safely to your cells. The result? You actually absorb what you pay for.

But here is the catch: making these microscopic bubbles is incredibly complex. If a manufacturer cuts corners, you don't get a liposome; you just get a vitamin mixed with some fat. And without transparency, you wouldn't know the difference until your customers complain that the product isn't working.

The Indicators of an Honest Manufacturer

So, how do you spot a partner who values an open-door policy versus one who is hiding something? You need to look for specific green flags.

1. The "Alphabet Soup" of Certifications

Anyone can say they follow "good practices." Few prove it. When you audit a manufacturer, look for the certifications that carry weight globally, especially if you sell in the US, UK, or India.

- GMP (Good Manufacturing Practice): This is non-negotiable. It means the facility is clean, controlled, and consistent.

- ISO 22000 & HACCP: These are international standards for food safety management.

- Specialized Certs: Halal and Kosher certifications show a manufacturer is meticulous enough to cater to specific dietary and religious standards.

At Samarth Biorigins, we don't just hang these certificates on the wall for decoration; they are the framework of our daily operations.

2. Third-Party Validation

If a manufacturer grades their own homework, they will always get an A+. That is why third-party testing is crucial. You should ask for a Certificate of Analysis (COA) for every batch. This document proves that what is on the label is actually in the drum, and that it’s free from heavy metals or contaminants.

3. Traceability: The Breadcrumbs

Can your manufacturer tell you exactly where their raw turmeric or iron came from? Supply chain traceability is vital. You need to know that the ingredients were sourced ethically and safely. If the paper trail ends at the factory door, that’s a red flag.

Why We Built a Glass House

Our obsession with transparency isn't a marketing gimmick—it’s woven into our DNA.

The story of Samarth Biorigins actually began during the chaos of the COVID-19 pandemic. It was a scary time for everyone. We saw a desperate need for health solutions that actually worked—specifically lactoferrin for its antiviral benefits. But we realized standard delivery methods weren't cutting it. The nutrients weren't being absorbed well enough to make a difference.

That frustration sparked a mission: to create liposomal ingredients that deliver superior bioavailability, backed by hard science.

We developed proprietary technologies like LipoDuo™ and Encapset™ to solve stability issues that plague standard formulations. But innovation means nothing if you can't trust the source.

That’s why we adopted an open-door policy. Whether you are a startup in London or a legacy brand in New York, we believe you deserve to know exactly how your ingredients are made. We share our documentation, we validate our results through clinical and in-vitro studies, and we commit to ethical sourcing.

The Bottom Line

The era of the "black box" manufacturer is over. Consumers are smarter, regulations are stricter, and brands can no longer afford to guess about quality.

When you choose a manufacturing partner, don't just look at the price tag. Look at the process. Look for the partner who invites you in, shows you the data, and treats your reputation as carefully as they treat their own.

Build trust. Choose transparency.

Ready to see what superior transparency looks like? Connect with Samarth Biorigins today and let’s build something extraordinary together.

You Might Like Also

Investing in a Double Rider Jacket: A Buyer's Guide

Trendy Ladies Studded Leather Jackets: NYC Leather Jackets Guide