Adjustable Tool Rests: These are platforms located on either side of the grinder wheel where the operator can rest the workpiece. Adjustable tool rests can be moved closer to or farther away from the grinding wheel to accommodate different workpiece sizes and grinding needs. They help maintain a safe distance between the operator's hands and the grinding wheel.

Eye Shields: Eye shields are transparent guards mounted above the grinding wheel to protect the operator's eyes from flying debris and sparks. They should be adjustable and positioned close to the grinding wheel to provide maximum protection while still allowing visibility of the workpiece.

Spark Deflectors: Spark deflectors are installed on the sides and back of the grinder to prevent sparks from flying out and potentially causing fires or injuries. They help contain sparks within the grinder's work area and protect nearby objects and personnel.

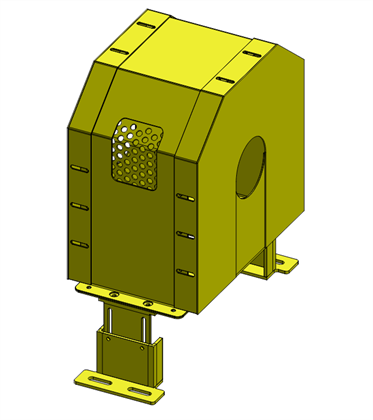

Wheel Guards: Wheel guards are enclosures that cover the grinding wheel to prevent operators from accidentally touching the rotating wheel. They are typically made of metal or durable plastic and should be securely attached to the grinder frame.

Emergency Stop Button: Bench grinder machines should be equipped with easily accessible emergency stop buttons to quickly halt machine operations in case of an emergency.

Tool Tray: Some bench grinders feature a tool tray mounted beneath the grinder wheels to hold tools, spare parts, or workpieces. This helps keep the work area organized and reduces the risk of accidents caused by clutter.

Anti-Vibration Mounts: Anti-vibration mounts or pads can be installed beneath the grinder to reduce vibrations and stabilize the machine during operation. This helps improve operator safety and prevents the grinder from moving or tipping over.

Safety Switches: Safety switches may be installed on the grinder to ensure that guards are properly positioned and secured before the machine can be operated. They help prevent accidents caused by missing or improperly installed safety guards.

You Might Like Also

chain belt drive guard

pump coupling safety guard

Lathe machine safety guard

safety guards

drilling machine safety guard

safety fence industrial