Chuck Guard: This guard covers the chuck and workpiece to prevent operators from coming into contact with rotating components. It typically consists of a transparent or solid barrier that allows visibility of the machining process while providing protection.

Lead Screw and Feed Rod Guard: Guards are placed around the lead screw and feed rod to prevent accidental contact. These guards are designed to allow smooth movement of these components while keeping operators safe.

Spindle Guard: This guard encloses the spindle area to prevent operators from reaching into the rotating spindle. It can be hinged or removable for tool changes and adjustments.

Chip Guard: A chip guard is placed around the cutting area to contain metal chips and debris generated during the machining process. It helps prevent injuries from flying debris and keeps the work area clean.

Emergency Stop Button: Although not a physical guard, an emergency stop button should be easily accessible to operators to quickly halt machine operations in case of an emergency.

Interlocking Safety Door: Some lathe machines are equipped with interlocking safety doors that prevent the machine from operating when the doors are open. This ensures that operators cannot access hazardous areas while the machine is running.

Safety Switches: Safety switches can be installed on various access points of the machine to ensure that guards are properly closed before the machine can be operated.

You Might Like Also

chain belt drive guard

pump coupling safety guard

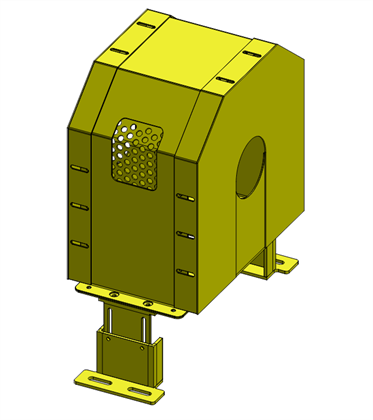

bench grinder machine safety guard

safety guards

drilling machine safety guard

safety fence industrial